Pick & place (placement) is an automatic machine, however, the machine requires careful calibration and programming in order to function at max capacity. Regardless of whether your business focuses on prototyping, quick turnaround assembly, or volume production, these risks of inefficiency and potential losses are lurking around the corner in your day-to-day operations;

There is no doubt that neither machine software systems nor traditional 3rd party software can solve these challenges due to their limitations.

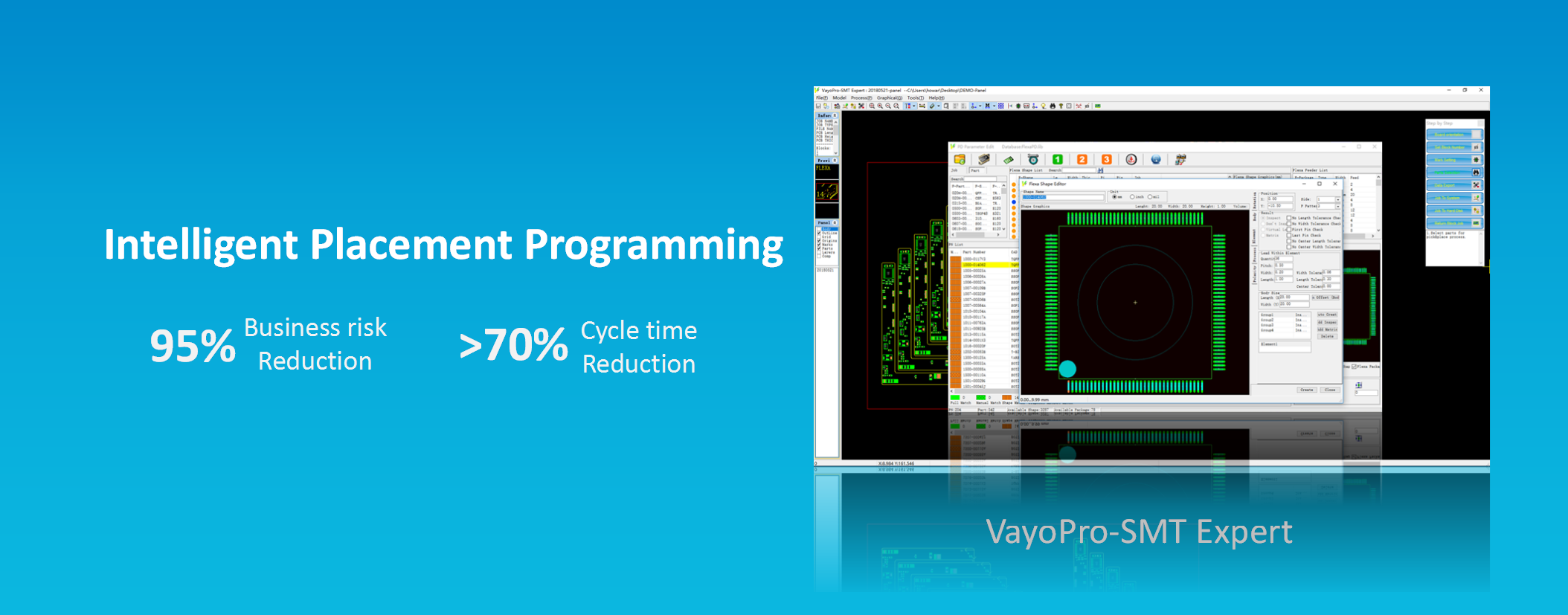

Vayo solves this systematic industry challenge with patented intelligent technology and applies a new intelligent accelerator approach to the mainstream placement machine platform one by one.

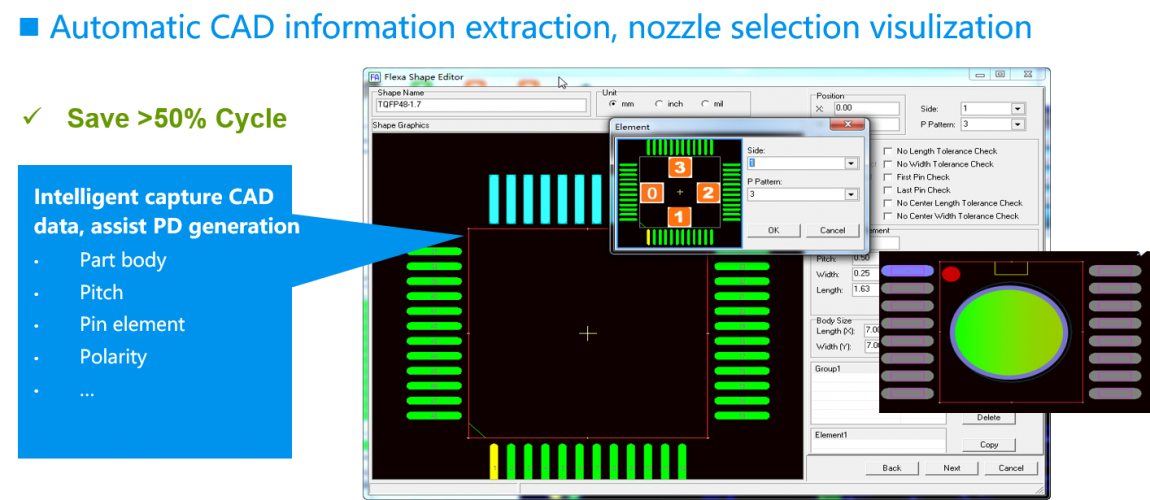

An intelligent accelerator simulates the actions of human beings and intelligently searches the best-matched part shape & package from the machine library. It also saves the cycle time and increases the accuracy of the assignment of part data.

Intelligent accelerator extracts footprint information from PCB CAD, which greatly saves the preparation time of parts outline and pin element.

Lack of synchronization between PCB designer and SMT programmer brings rotation/polarity correction challenges. A small issue on paper can lead to multiplicative complications down the road, with real-world consequences (customer complaints, lost orders, or lost business).

New intelligent accelerator converts a manual approach to an intelligent one, which reduces 95% of the business risk that stems from the wrong polarity, and saves both offline & inline programming cycle time.

VayoPro-SMT Expert can not only support powerful manual imposition functions, but also intelligently generate puzzles from pictures drawn by CAD or Gerber data sources; it can also reduce the cycle time of imposition production from a few hours to one minute.

SMT Expert supports CAD sources like Cadence Allegro/OrCAD, Mentor, PowerPCB, Altium/Protel, Zuken, ODB++, IPC-2581, Accel, and more; it then validates BOM content and performs cross verification with CAD. If there is no CAD source, you can also load centroid XY data with a Gerber data source.

For placement platforms that do not currently have an intelligent accelerator function ready, Vayo has your back with comprehensive support for traditional offline programming approaches.

SMT Expert can automatically generate and feed a loading list and assembly drawing. This method greatly reduces the cycle time of document preparation. Moreover SMT Expert can validate your existing program so as to reduce programmatical errors caused by ECO change, personnel turnover, or other glitches occurring due to incorrect operation.

SMT Expert can perform machine program conversions between Fuji, ASM, Panasonic & Yamaha; it also greatly speeds up the line transfer process for customers who have multiple machine platforms.

The Vayo team keeps improving existing SMT Expert functions and features, and strives to deliver more value to our customers that exceed their expectations.